270m3 Capacity Polyvinyl Chloride Shoe Injection Molding Machine For Footwear

-

Highlight

270m3 capacity shoe injection molding machine

,polyvinyl chloride shoe injection molding machine

,270m3 capacity footwear injection moulding machine

-

Power27kw

-

Hs Code8504101000

-

Forming SpeciesCup

-

Automatic GradeAutomatic

-

Guarantee1year

-

Specification1400*700*1200mm

-

Mould Clamping Force60/80/100ton

-

Injection Capacity270m³

-

Place of OriginChina

-

Brand NamePVC Injections machine

-

Model NumberKK-AM005

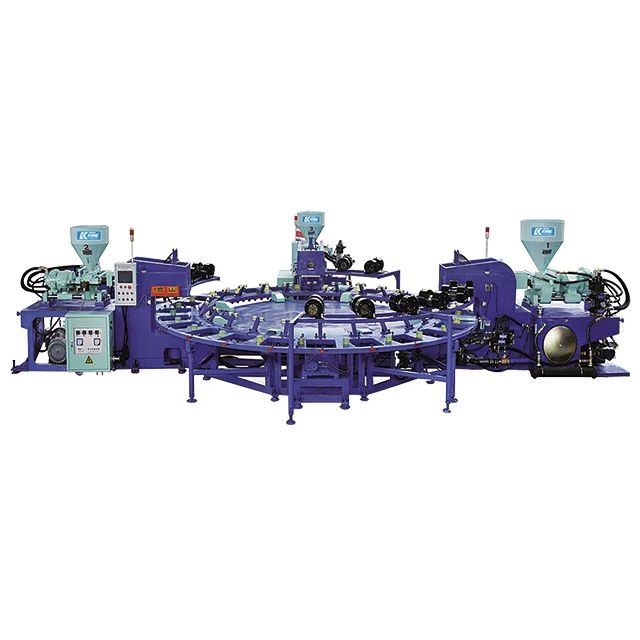

270m3 Capacity Polyvinyl Chloride Shoe Injection Molding Machine For Footwear

Product Description:

The PVC Injection Molding Shoe Machine is a highly efficient and advanced equipment designed specifically for the production of PVC shoes. It is also known as the Polyvinyl Chloride Shoe Injection Molding Machine, which is widely used in the footwear industry for its superior performance and high precision.

This machine is powered by a strong 27kw motor, providing a stable and powerful force for the production process. It is designed to meet the strict standards of the industry and is capable of producing high-quality PVC shoes with great efficiency.

The HS Code for this product is 8504101000, which indicates its classification as a machinery and mechanical appliance. This code is used for customs and international trade purposes.

The PVC Injection Molding Shoe Machine is specifically designed for forming species of cup-shaped shoes. This means it is capable of producing a variety of cup-shaped designs, providing flexibility and versatility in shoe production.

The plasticizing way of this machine is plunger type, which ensures a smooth and uniform plasticizing process. This method of plasticizing is known for its high efficiency and precision, ensuring the quality and consistency of the final product.

The dimensions of this machine are 1400*700*1200mm, making it compact and space-saving. This size also allows for easy installation and operation in any shoe manufacturing facility.

In conclusion, the PVC Injection Molding Shoe Machine is an essential equipment for any footwear manufacturer looking to produce high-quality PVC shoes. Its powerful motor, efficient plasticizing method, and compact size make it a top choice for the industry. So, if you are looking for an efficient and reliable PVC Shoe Injection Molding Equipment, look no further than the PVC Shoe Injection Molding Equipment!

Features:

- Product Name: PVC Injection Molding Shoe Machine

- Hs Code: 8504101000

- Plasticizing Way: Plunger Type

- Forming Species: Cup

- Injection Capacity: 270m³

- Screw Diameter: 65 Or 75

- PVC Injection Molding Machine for Shoes

- PVC Shoe Injection Molding Production Line

- PVC Shoe Injection Molding System

Technical Parameters:

| Technical Parameters | Value |

|---|---|

| Forming Species | Cup |

| Automatic Grade | Automatic |

| Screw Diameter | 65 or 75 |

| Guarantee | 1 year |

| Specification | 1400*700*1200mm |

| Product_Machine_Weight | 2-5 Tons |

| Mould Clamping Force | 60/80/100ton |

| Machine Weight | 8 tons |

| Plasticizing Way | Plunger Type |

| Work Station | 8 |

| Product Name | PVC Shoe Injection Molding Equipment |

|---|---|

| Alternative Names | PVC Footwear Injection Molding Machinery, Polyvinyl Chloride Shoe Injection Molding Machine, PVC Injection Molding Shoe Production Line |

| Forming Species | Cup |

| Automatic Grade | Automatic |

| Screw Diameter | 65 or 75 |

| Guarantee | 1 year |

| Specification | 1400*700*1200mm |

| Product_Machine_Weight | 2-5 Tons |

| Mould Clamping Force | 60/80/100ton |

| Machine Weight | 8 tons |

| Plasticizing Way | Plunger Type |

| Work Station | 8 |

Applications:

Brand Name: PVC Injections machine

Model Number: KK-AM005

Place of Origin: China

Injection Capacity: 270m³

Work Station: 8

Mould Clamping Force: 60/80/100ton

Voltage: 380v 50hz

Screw Diameter: 65 Or 75

The PVC Injection Molding Shoe Machine, also known as PVC Shoe Making Injection Molding Machine or PVC Shoe Manufacturing Injection Molding Machine, is a specialized equipment used to produce high-quality PVC shoes. It is mainly used in shoe manufacturing factories, footwear production lines, and other related industries.

- High Injection Capacity: This machine has an injection capacity of 270m³, allowing for efficient and fast production of PVC shoes.

- Multiple Work Stations: The machine is equipped with 8 work stations, which can simultaneously produce 8 pairs of shoes, increasing productivity and reducing production time.

- Mould Clamping Force: With a mould clamping force of 60/80/100ton, this machine can securely hold the mould in place during the injection process, ensuring precise and accurate production.

- Stable Voltage: The machine operates on a stable voltage of 380v 50hz, ensuring a smooth and continuous production process.

- Versatile Screw Diameter: The machine is equipped with a screw diameter of either 65 or 75, allowing for flexibility in production and catering to different shoe sizes and shapes.

The PVC Injection Molding Shoe Machine is suitable for various application scenarios, including but not limited to:

- Shoe manufacturing factories: This machine can be used in factories that specialize in producing PVC shoes, such as sports shoes, sandals, and slippers.

- Footwear production lines: The machine can be integrated into a footwear production line, where it can efficiently produce high-quality PVC shoes in bulk.

- Custom shoe orders: With its precise injection process and versatile screw diameter, the machine can cater to custom shoe orders, providing a wide range of options for customers.

The PVC Injection Molding Shoe Machine, with its high injection capacity, multiple work stations, stable voltage, and versatile screw diameter, is an essential equipment for PVC shoe production. Its application in various scenarios makes it a valuable asset for shoe manufacturers and contributes to the production of high-quality PVC shoes in the market.

Customization:

Introducing our top-of-the-line PVC Footwear Injection Molding Machinery – the perfect solution for all your shoe production needs. Our PVC Shoe Making Injection Molding Machine, Model KK-AM005, is designed and manufactured in China with the highest quality standards.

With a machine weight of 8ton and a mould clamping force of 60/80/100ton, our PVC Injection Molding Shoe Machine is durable and efficient, capable of handling high-volume production with ease. The screw diameter of 65 or 75 ensures precise control over the injection process, while the plunger type plasticizing way guarantees a smooth and consistent output.

At our company, we understand that every customer has unique needs and requirements. That's why we offer customized service for our PVC Footwear Injection Molding Machinery, tailoring the machine to fit your specific production needs. Our team of professionals will work closely with you to provide a personalized solution that meets your exact specifications.

With our advanced technology and years of experience in the industry, we are able to deliver high-quality, reliable, and versatile machines that will exceed your expectations. Our PVC Shoe Making Injection Molding Machine is user-friendly, making it easy for your operators to learn and operate, resulting in increased productivity and efficiency.

Investing in our PVC Injection Molding Shoe Machine means investing in a long-term solution for your shoe production needs. Our machines are built to last, with durable components and a sturdy construction that can withstand the demands of a busy production facility. Trust us to provide you with a professional and reliable machine that will help you take your shoe production to the next level.

Choose our PVC Footwear Injection Molding Machinery and experience the difference in quality, efficiency, and durability. Contact us now to learn more about our customized service and how we can help you achieve your production goals.

Packing and Shipping:

The PVC Injection Molding Shoe Machine will be carefully packaged to ensure safe delivery to our customers. Each component will be securely wrapped and placed in a sturdy wooden crate for maximum protection during transport. The crate will be labeled with the product name and model number for easy identification.

We offer various shipping options to meet the needs of our customers. The PVC Injection Molding Shoe Machine can be shipped by sea, air, or land, depending on the destination and urgency of the order.

For international shipments, we will handle all necessary customs and documentation requirements to ensure a smooth delivery process.

Once the product is shipped, we will provide our customers with a tracking number so they can monitor the progress of their order.

We strive to ensure timely delivery of our products and will work with our customers to accommodate any specific shipping requests.

FAQ:

- Q: What is the brand name of this product?

- A: The brand name of this product is PVC Injections machine.

- Q: What is the model number of this product?

- A: The model number of this product is KK-AM005.

- Q: Where is this product made?

- A: This product is made in China.

- Q: What type of material can be used with this machine?

- A: This machine is designed for PVC injection molding.

- Q: Is this machine suitable for producing different sizes of shoes?

- A: Yes, this machine can be adjusted to produce shoes of different sizes.

- Q: How many pairs of shoes can be produced per hour with this machine?

- A: The production capacity of this machine depends on the size and complexity of the shoes, but it can produce up to hundreds of pairs per hour.