220V Boot Assembly Machines PVC Airblowing Machine Designed for Footwear Manufacturers Seeking Durable and Assembly Line Solutions

-

Highlight

220V PVC boot assembly machine

,airblowing machine for footwear manufacturers

,durable shoe making assembly line

-

Machinery Test ReportNot Available

-

Screw Rotation Speed0-140r.p.m

-

Welding Speed0.5~5m/min

-

Stamping Area90*80mm

-

Marking Depth0.005-1mm,Real-time Tunable

-

Pressure220V

-

Mold Height70-260mm

-

Laser Output Power365mm 3/5/10

-

Brand NameShoe Making Machines

-

Model NumberKK-HT-A01

-

Payment TermsTT

220V Boot Assembly Machines PVC Airblowing Machine Designed for Footwear Manufacturers Seeking Durable and Assembly Line Solutions

Product Description:

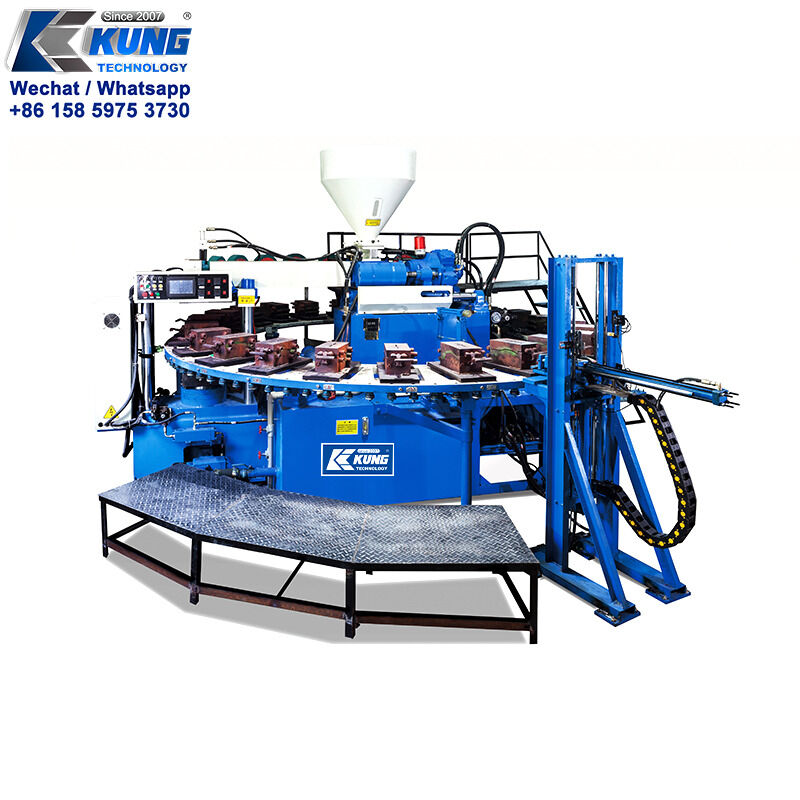

The Shoe Making Machines are advanced and efficient solutions designed specifically for the footwear industry. As essential components of Footwear Production Equipment, these machines play a critical role in streamlining the shoe manufacturing process, ensuring precision, durability, and high-quality output. Built with cutting-edge technology, the Shoe Making Machines cater to a wide range of shoe styles and production volumes, making them indispensable for modern shoe factories and workshops.

One of the standout features of these Shoe Manufacturing Machines is their rotary style design. The rotary mechanism allows continuous and smooth operation, significantly enhancing productivity and reducing downtime. This style is particularly beneficial for large-scale footwear production, where consistent performance and speed are crucial. The innovative rotary system also ensures uniform pressure distribution during the shoe making process, resulting in superior bonding and finishing quality of the footwear.

The machines are equipped with molds that have a height range from 70mm to 260mm, providing great flexibility in manufacturing different types and sizes of shoes. This wide mold height range makes the machines suitable for producing everything from casual shoes to boots, accommodating various design requirements and fashion trends. Manufacturers can easily switch between molds to meet diverse customer demands without compromising on efficiency or quality.

Precision is a key aspect of the Shoe Manufacturing Machines, and this is reflected in their marking depth capability. With a real-time tunable marking depth ranging from 0.005mm to 1mm, these machines allow operators to adjust the depth according to specific materials and design needs. This precise control ensures that each shoe produced meets exact standards, improving the overall aesthetic and structural integrity of the footwear. The ability to tune marking depth on the fly also enhances customization options, enabling manufacturers to create unique patterns and textures on shoe surfaces.

In terms of power and operational efficiency, the Shoe Making Machines operate on a standard 220V pressure system. This voltage specification ensures compatibility with common industrial power supplies, simplifying installation and maintenance. The 220V pressure system also guarantees stable and consistent performance, which is vital for maintaining the quality of shoe manufacturing processes. By utilizing reliable pressure control, the machines minimize material waste and reduce the risk of defects, contributing to cost-effective production.

Another practical consideration is the shipping and logistics options available for these Shoe Manufacturing Machines. They can be shipped from either the Ningbo or Wenzhou ports, two of China’s major shipping hubs known for efficient handling and timely dispatch. This flexibility in port selection allows manufacturers to optimize their supply chain and reduce lead times, facilitating smoother business operations and faster market delivery.

Overall, these Shoe Making Machines represent a comprehensive solution for footwear manufacturers seeking to enhance their production capabilities. Combining advanced rotary technology, adjustable mold heights, precise marking depth control, and reliable 220V pressure operation, the machines are tailored to meet the evolving demands of the footwear industry. Whether producing athletic shoes, formal footwear, or specialized designs, these machines provide the necessary features and performance to achieve high-quality results consistently.

Investing in these Shoe Manufacturing Machines means gaining access to state-of-the-art Footwear Production Equipment that supports innovation, efficiency, and scalability. Their robust design and versatile specifications make them suitable for a variety of manufacturing environments, from small workshops to large-scale factories. By integrating these machines into the production line, manufacturers can improve product quality, increase output speed, and reduce operational costs, ultimately enhancing competitiveness in the global footwear market.

In conclusion, the Shoe Making Machines shipped from Ningbo or Wenzhou ports, featuring mold heights from 70 to 260mm, real-time tunable marking depths between 0.005mm and 1mm, rotary style operation, and 220V pressure systems, are an excellent choice for any footwear production enterprise. They embody the latest advancements in Shoe Manufacturing Machines technology and provide a reliable foundation for producing top-tier footwear that meets modern consumer expectations.

Technical Parameters:

| Marking Depth | 0.005-1mm, Real-time Tunable |

| Stamping Area | 90*80mm |

| Style | Rotary |

| Port | Ningbo Or Wenzhou |

| Max Roller Gap | 10mm |

| Screw Rotation Speed | 0-140r.p.m |

| Mold Height | 70-260mm |

| Use | Foam, Fabric, And Rubber Cutting |

| Keyword | PVC Airblowing Machine |

| Power Supply | 35.0KW |

Applications:

The Shoe Making Machines, model number KK-HT-A01, originating from China, represent a cutting-edge solution in the footwear manufacturing industry. Designed with a rotary style mechanism, these Shoe Fabrication Machines are engineered to enhance efficiency and precision in various shoe production processes. With a stamping area of 90*80mm, the machine is ideally suited for detailed cutting tasks involving materials such as foam, fabric, and rubber, which are essential components in modern footwear manufacturing.

These Shoe Fabrication Machines are particularly valuable in footwear production environments where versatility and speed are critical. The screw rotation speed, adjustable from 0 to 140 r.p.m, allows operators to customize the cutting process according to the material thickness and type, ensuring optimal results without compromising material integrity. This feature makes the KK-HT-A01 model an indispensable piece of Footwear Production Equipment for factories aiming to maintain high throughput while ensuring quality craftsmanship.

The Shoe Making Machines are suitable for a wide range of application occasions and scenarios. In large-scale shoe manufacturing plants, they streamline the cutting of components, reducing manual labor and increasing consistency across production batches. Smaller workshops and bespoke shoe producers also benefit from their precision and adaptability, enabling the creation of custom footwear designs with intricate patterns and shapes.

Due to their robust construction and reliable performance, these machines are perfect for use in environments where foam, fabric, and rubber components require precise and repeatable cutting. Whether producing sports shoes, casual footwear, or specialized safety shoes, the KK-HT-A01 model enhances productivity and product quality. Although the machinery test report is not available, the brand's reputation and the machine’s technical specifications demonstrate its capability and suitability for modern footwear manufacturing demands.

Payment terms such as TT make the procurement process straightforward, further encouraging adoption by manufacturers worldwide. In summary, the Shoe Making Machines KK-HT-A01 are essential Footwear Production Equipment that support a variety of shoe fabrication needs, making them a valuable investment in the competitive footwear industry.

Customization:

Our Shoe Making Machines, model KK-HT-A01, are premium Footwear Production Equipment designed to meet your specific manufacturing needs. Originating from China, this rotary-style machine offers customizable features such as mold height ranging from 70 to 260mm, welding speeds adjustable between 0.5 to 5 meters per minute, and a real-time tunable marking depth from 0.005 to 1mm. The screw rotation speed can be precisely controlled from 0 to 140 r.p.m, ensuring optimal performance for various shoe production requirements. We accept TT payment terms to facilitate a smooth transaction process. Trust our Shoe Manufacturing Machines to enhance your production line with advanced technology and reliable customization options tailored to your footwear manufacturing demands.