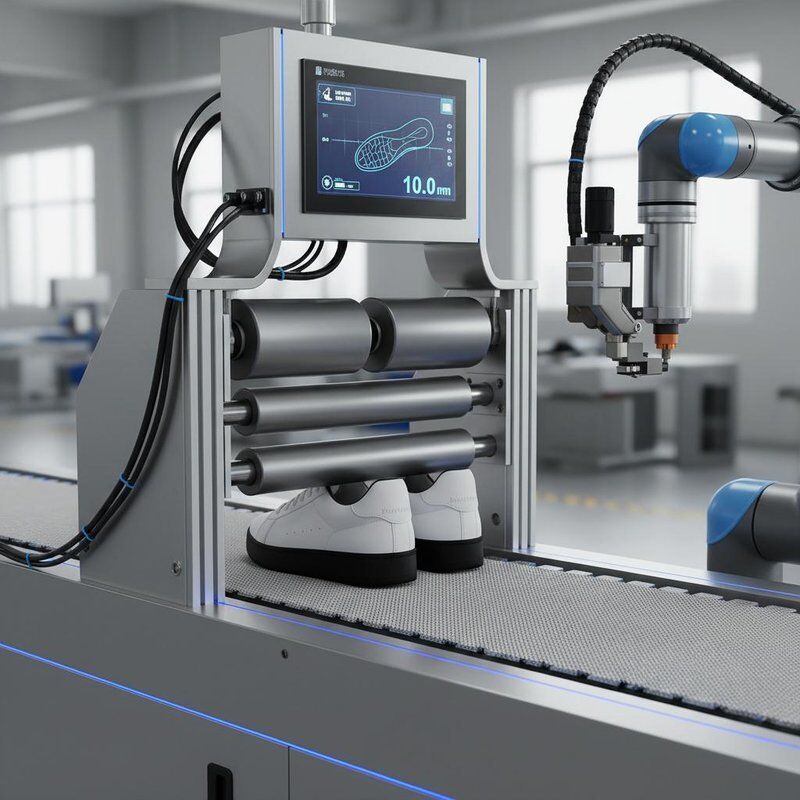

Real-time Tunable Marking Depth Footwear Production Equipment with Max Roller Gap 10mm Supporting and Precise Shoe Assembly

-

Highlight

tunable depth footwear production machine

,shoe assembly machine with 10mm roller gap

,precise shoe making equipment with warranty

-

Laser Output Power365mm 3/5/10

-

KeywordPVC Airblowing Machine

-

Mold Height70-260mm

-

Work Station46/60/80

-

Max Roller Gap10mm

-

Stamping Area90*80mm

-

Marking Depth0.005-1mm,Real-time Tunable

-

PortNingbo Or Wenzhou

-

Brand NameShoe Making Machines

-

Model NumberKK-HT-A01

-

Payment TermsTT

Real-time Tunable Marking Depth Footwear Production Equipment with Max Roller Gap 10mm Supporting and Precise Shoe Assembly

Product Description:

The Shoe Making Machines, designed with an advanced rotary style, represent a significant innovation in the field of shoe production technology. These machines are engineered to meet the diverse and demanding needs of modern footwear manufacturing, ensuring precision, efficiency, and reliability throughout the shoe fabrication process. With their robust construction and state-of-the-art features, these rotary shoe making machines have become an indispensable asset for industries involved in boot assembly and shoe manufacturing.

One of the standout features of these shoe making machines is their marking depth capability, which ranges from 0.005mm to 1mm. This marking depth is real-time tunable, allowing operators to make precise adjustments according to the specific requirements of different shoe components. The ability to finely tune the marking depth ensures that the machines can handle a variety of materials and thicknesses commonly encountered in shoe fabrication. This flexibility makes them ideal for producing high-quality footwear with intricate designs and detailed markings, essential for both aesthetic appeal and functional performance.

Powering these machines is a robust 35.0KW power supply, which guarantees consistent and reliable operation even during intensive manufacturing cycles. The substantial power capacity supports the high demands of continuous production, making these shoe manufacturing machines suitable for large-scale industrial applications. This power supply also enhances the machine’s ability to maintain precision and speed, reducing downtime and increasing overall productivity in boot assembly lines.

Another critical specification is the laser output power, with options available at 3W, 5W, and 10W, combined with a 365mm laser source. The laser technology integrated into these shoe making machines provides exceptional accuracy and control during the marking and cutting processes. This laser output power range allows the machines to handle various materials, from delicate fabrics to tougher leather and synthetic components, which are often used in shoe fabrication. The precision offered by laser technology not only improves the quality of the finished product but also minimizes material wastage, contributing to more sustainable manufacturing practices.

Despite the advanced features and capabilities, it is important to note that a machinery test report is not available for these shoe making machines at this time. However, the machines have been developed following stringent quality standards and undergo rigorous internal testing to ensure they meet the performance expectations of shoe manufacturing professionals. Potential buyers are encouraged to consult directly with manufacturers or authorized distributors to obtain detailed product information and verify suitability for their specific production needs.

In summary, these rotary style shoe making machines are a powerful solution for industries involved in boot assembly, shoe fabrication, and overall shoe manufacturing. Their real-time tunable marking depth, substantial power supply, and versatile laser output power make them highly adaptable to a wide range of production environments. Whether producing casual footwear, specialized boots, or high-end designer shoes, these machines provide the precision and efficiency necessary to elevate the manufacturing process. Their integration into shoe production lines can significantly enhance output quality, reduce processing times, and increase operational efficiency, making them a valuable investment for any footwear manufacturer aiming to stay competitive in today's market.

Technical Parameters:

| Power Supply | 35.0KW |

| Keyword | PVC Airblowing Machine |

| Mold Height | 70-260mm |

| Max Roller Gap | 10mm |

| Marking Depth | 0.005-1mm, Real-time Tunable |

| Machinery Test Report | Not Available |

| Screw Rotation Speed | 0-140r.p.m |

| Port | Ningbo Or Wenzhou |

| Stamping Area | 90*80mm |

| Work Station | 46/60/80 |

This PVC Airblowing Machine is an ideal choice for Boot Assembly Machines, Shoe Manufacturing Machines, and Sole Making Equipment.

Applications:

The Shoe Making Machines, model number KK-HT-A01, originating from China, are designed to cater to a wide range of shoe manufacturing needs. These machines are ideal for various application occasions and scenarios in the footwear industry, providing reliable and efficient solutions for both small-scale workshops and large-scale factories. With a powerful 35.0KW power supply and a versatile rotary style, these Shoe Manufacturing Machines ensure high productivity and consistent quality in shoe production.

One of the primary application scenarios for the KK-HT-A01 Shoe Making Machines is in large shoe manufacturing plants where multiple workstations are required. Available with options of 46, 60, or 80 workstations, these machines can handle high-volume production runs, making them suitable for factories producing sports shoes, casual footwear, and formal shoes. The stamping area of 90*80mm allows for precise and efficient stamping operations, contributing to the accuracy and aesthetic appeal of the final product.

These Shoe Manufacturing Machines are also perfectly suited for specialized shoe manufacturing shops focusing on custom designs or limited edition footwear. The rotary style of the machine facilitates continuous and smooth operation, which is essential for maintaining production speed while ensuring detailed craftsmanship. Additionally, the machine’s compatibility with TT payment terms and shipping availability through ports like Ningbo or Wenzhou makes it accessible for businesses worldwide.

In scenarios where durability and efficiency are paramount, such as in industrial-scale shoe production, the KK-HT-A01 excels by offering robust performance and adaptability. Whether the requirement is for assembling, stitching, or stamping components of shoes, these Shoe Manufacturing Machines provide an integrated solution that reduces labor costs and improves turnaround times.

Furthermore, the Shoe Making Machines are ideal for educational institutions and training centers specializing in footwear design and manufacturing. They provide hands-on experience with advanced machinery, preparing students for careers in the footwear industry. Overall, the KK-HT-A01 model is a versatile and indispensable tool across various shoe manufacturing occasions, from mass production to specialized craftsmanship, ensuring efficiency, precision, and quality in every pair of shoes produced.

Customization:

Our Shoe Making Machines, model number KK-HT-A01, offer exceptional customization services tailored to meet your specific shoe manufacturing needs. Manufactured in China, these Shoe Manufacturing Machines are designed to deliver high performance and reliability, featuring a power supply of 35.0KW and a screw rotation speed ranging from 0 to 140 r.p.m.

The customization options include adjustable laser output power of 365mm with settings of 3/5/10, and a welding speed adjustable between 0.5 to 5 meters per minute, ensuring precise and efficient shoe fabrication. With ports available at Ningbo or Wenzhou, we provide flexible logistics solutions to suit your location.

Our Shoe Fabrication Machines are built to accommodate various production requirements, supported by convenient payment terms through TT. Choose our Shoe Manufacturing Machines for cutting-edge technology and customizable features that enhance your shoe production process.